I got this idea (actually I tried to duplicate/steal the project) from Alan Stratton who has a YouTube Channel called AsWoodTurns. Since I purchased my lathe and placed it in the shop in the basement, I have struggled with how to light the work area adequately. I have a 4 foot flourescent in the room, but I block the light as I stand between the light and the lathe. As a “temporary” fix, I hung a trouble light on a hook on the wall above the lathe. The only reason I don’t like that is that half the time when I look up, I get blinded by staring into a bare bulb. I have been looking for a light fixture that I could suspend on the ceiling over the lathe (much like a bathroom light fixture) and thought I would make one, I just haven’t found the right design. I have numerous puck lights from Ikea and thought that I would use those.

Anyway, before I bought my lathe I saw Alan’s video and thought that these lights would be perfect (at least to direct light exactly where it’s needed).

I picked up 2 of them from Ikea ($11.99 each) and they have sat in my shop for almost a year. I tried to figure out a way to make them early on as I hoped they would be my first projects on the lathe, but I couldn’t figure out how to make them without a scroll chuck. Now that I have a newly acquired scroll chuck I decided that there is no time like the present.

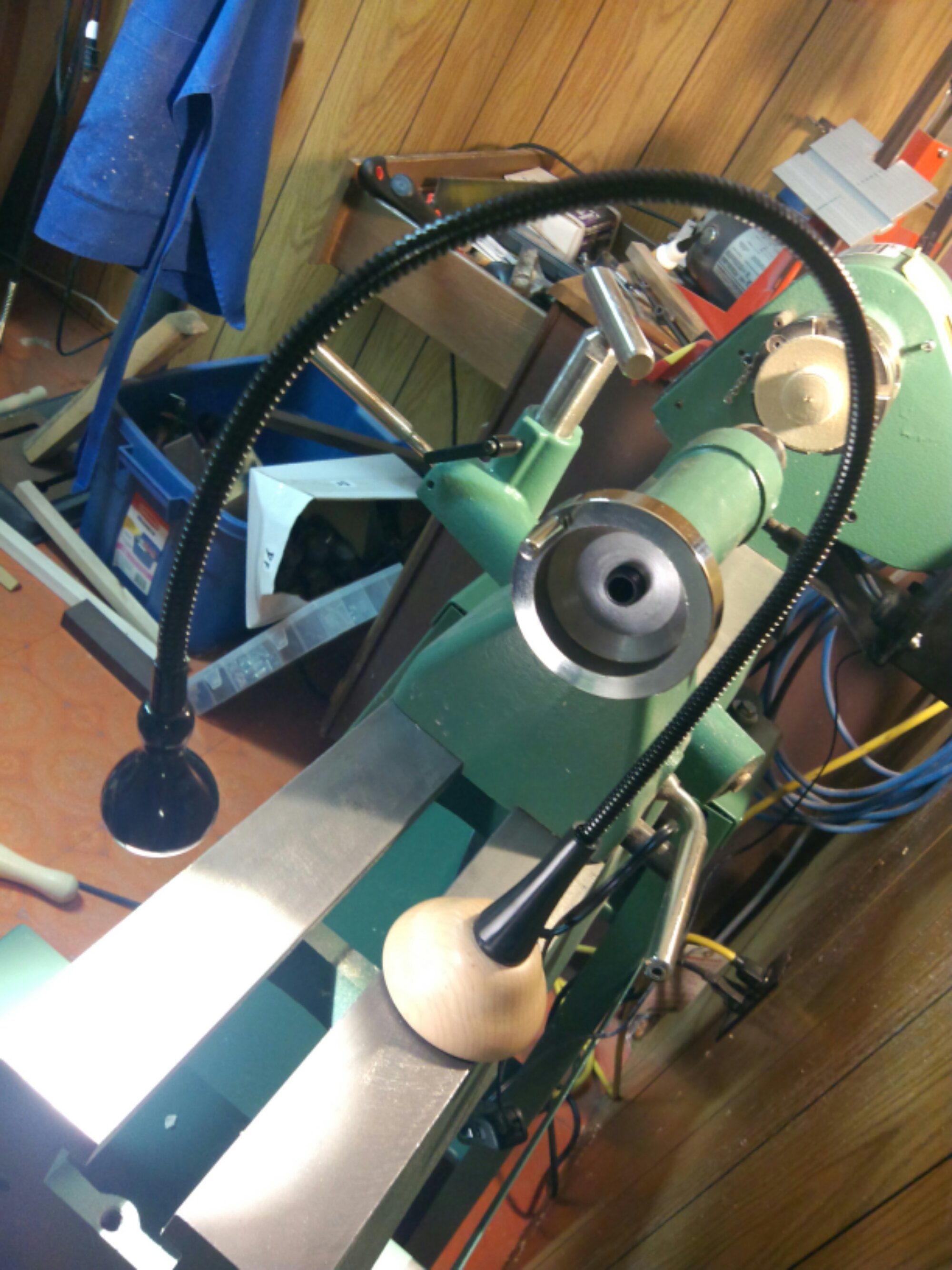

I had to utilize some of my own puny brainpower to do them but learned a few new techniques. I watched Alan’s video before I started but several points were not clear, so I just started and adapted as I went along. The first thing I did was true up a piece of Maple between centres and turned a tenon so that I could chuck it in the scroll chuck. Before I chucked it up, I drilled two holes for the pins on the bottom of the light. I didn’t quite get them centred on either side of the centre, but I don’t really notice. Next, I chucked it in my Talon and turned another tenon on the other end. This was somewhat pointless as I could have used the first tenon as the top, but wasn’t thinking clearly. Once chucked on the Talon, I cut the recess in piece for the magnet that attaches to the bottom. Then I had to drill a larger hole to countersink the screw and washer on the end of the posts so that I could actually attach the magnet. Then I flipped the piece over to shape the top. In Alan’s video, he used longneck (?) jaws in his chuck to expand into the magnet recess. My magnet was too small to have my jaws do that, so I made my first jamchuck (below) that held the piece in place while I was finishing the top.

The pin you see here was a snug fit on the recess. This worked perfectly and I will use it for my next one as well. All in all it was a good afternoon in the shop. I finish sanded to 420 grit and then used the EEE Cream. As it is a shop item, I don’t really think it is important to put a premium finish on it.

For the next one, I won’t turn a tenon on both sides and I will be more careful about centering the posts between the centres. I will also attach the magnet before I apply the teflon cover on the magnet which prevents scratches on the metal. Also, because I made the jamchuck to fit the recess, I will have to take some time to ensure that the next recess fits the jamchuck as nicely as this one did.